Hybrid Rocket Nozzle

After leaving Washington & Jefferson College and transferring to Columbia University as part of a 3+2 engineering program, I was ready to blast off into my studies as a mechanical engineer.

In the 2023-2024 academic year, I worked, as part of the Columbia Space Initiative Rocketry team, to develop a hybrid rocket nozzle for that year’s competition rocket.

Let’s just say it was… explosive

-

As part of a team of six, I was focused on the propulsion and combustion chamber side of the hybrid rocket design.

I was the primarily in charge of:

Designing and optimizing a rocket nozzle to produce design thrust.

Evaluating nozzle designs to minimize weight while maintaining strength.

Maintaining nozzle design in static fire testing to ensure continued use.

-

CNC & CAD/CAM, FEA, CFD, Thermal Analysis, Non-linear FEA, Propulsion and Amateur Rocketry Theory

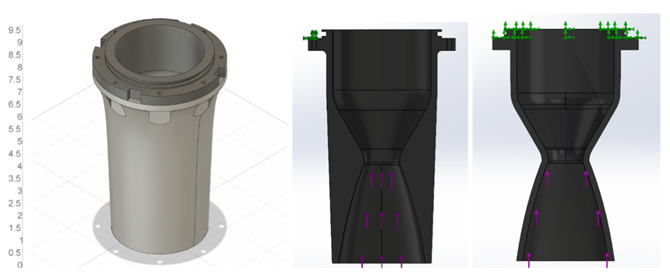

Design Overview

A rocket nozzle composed of aluminum with a graphite throat to obtain a design thrust of ~900lbf.

Flanged connection to interface with the rocket combustion chamber and withstand thrust forces during operation.

Iterative Design Process

Given thrust parameters by the greater design board, it was the objective of my team to provide a rocket nozzle that met these goals, while staying well underweight and structurally sound. My team initially decided to fabricate the nozzle out of a graphite composite. After it was designed, I completed FEA and CFD analysis to ensure that it met the design specifications.

When running the FEA on the nozzle, I noticed large stress concentrations at the flange, connecting the nozzle to the combustion chamber. This was concerning to me as graphite is a extremely brittle material, though a great thermal conductor.

With this realization, I recommended an alteration in the design, where a graphite throat was embedded within an aluminum shell. That way, the aluminum was protected from the intense heat of the combustion, while preventing a failure at the nozzle flange.

Outcome

Due to the work from me and my team, the Columbia Rocketry team was able to complete it’s rocket and launch it at competition. The hybrid fuel, nitrous-paraphin rocket surpassed its predecessors at the summer competition, scoring 2nd Place in its launch category.