Full Flow Rocket Engine Analysis

My last semester at Columbia, I was enrolled in Advanced Graduate Thermodynamics. As part of the course, I was instructed to complete a research project on a topic of my choosing. I chose to analyze the Raptor 3 Full Flow Rocket Engine!

*pause for shock and awe*

Myself and one other engineer worked to model this engine using Python, CoolProp, and our knowledge of thermodynamics and combustion.

-

As part of a team of two, I worked to model the thermodynamics of a full flow rocket engine.

I was the primarily in charge of:

Creating an engine model.

Applying specific conditions to the model.

Calculating and plotting interesting engine parameters.

-

Python, CoolProp, Thermodynamics, Combustion, Data Analysis

Design Overview

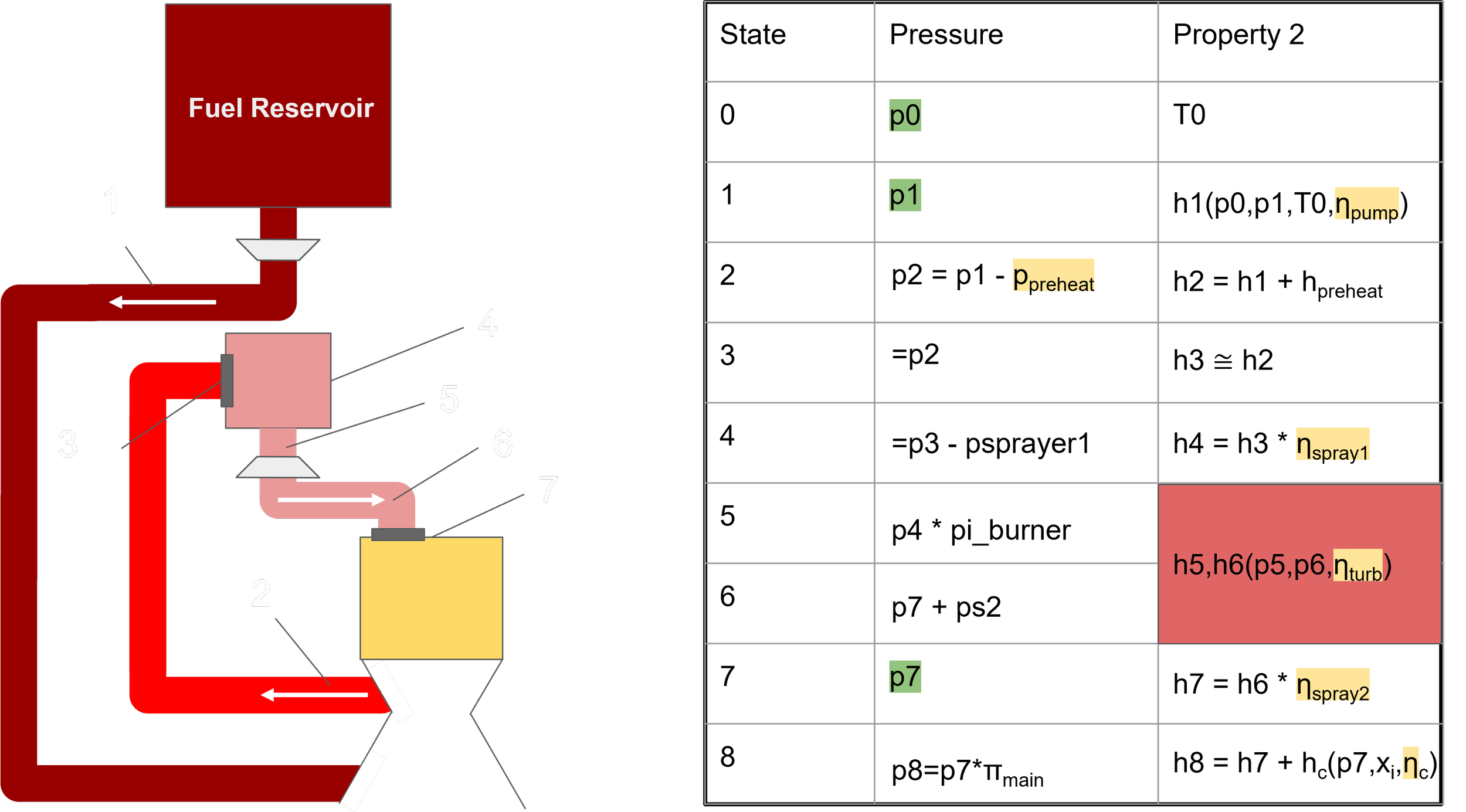

The design of this rocket model was based off of SpaceX’s Raptor 3 Engine. Seen below is the engine diagram that was utilized in the analysis.

Using this model, states could be prescribed to the fluids in each stage of the rocket engine, giving insight into the rocket’s functionality.

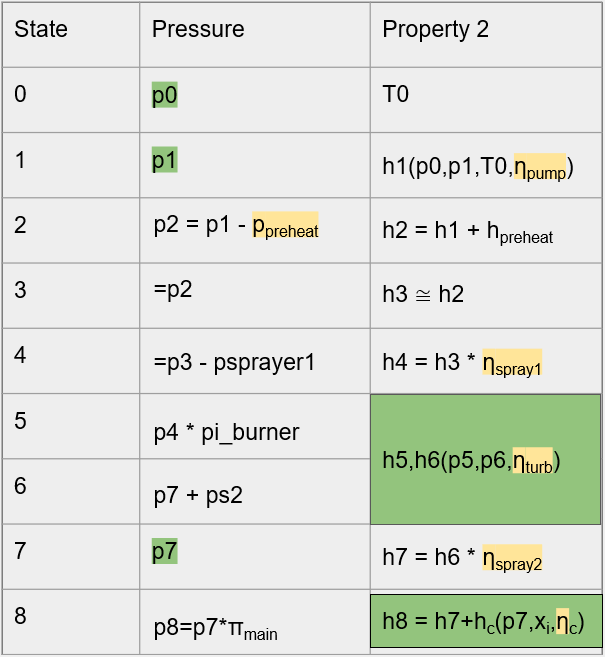

Fluid States: Fuel Side

With states assigned from publicly accessible data to most fluid stages, the remaining states can be approximated thermodynamically.

This was done by assigning assumed efficiencies to fuel pumps, pre-burners and turbines, and using the CoolProp python package to approximate the thermodynamic states of the engine fluid.

To approximate the enthalpies at states 5 and 6 (before and after the main combustion), some assumptions about the combustion had to be made.

Combustion Model

To predict the major products, the water-gas shift reaction was utilized along with the major-minor species model from combustion theory. This provided us with the relationship seen below.

This plot shoes that as we move from fuel rich to fuel lean, the major products of combustion become Carbon Dioxide and Water.

With this information, some insights into the efficiencies of the rocket engine were found.

An interesting thing noted in this data was the fact that the maximum payload capacity, specific impulse, and propulsive efficiency all peak at ~1.8 oxygen to fuel ratio. It is evident that less oxidizer consumption as the mixture becomes richer is favorable as compared to near stoichiometric conditions.

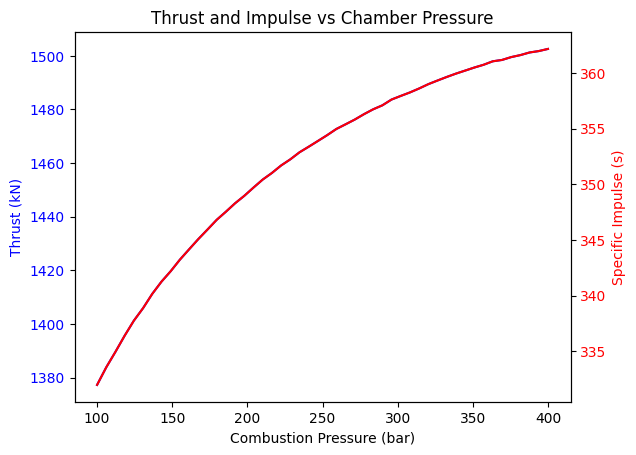

Outcome

From this project, I learned a great deal about the operation of full flow rocket engines and their operating constraints. Obviously infinitely high combustion chamber pressure would result in an ideal thrust condition, however the structural limitations of real materials make this impossible. For the full comprehensive report on this project, click here.