H-Ohm Strength

On the first day of class, senior year at Columbia, my fellow classmates and I are told to “Find a problem! No, not just any problem, but one that has potential for a NOVEL solution.”

My team and I took this charge and decided to develop a unique, self-powered, cable machine that could bring a workout experience you might find in a commercial gym to any consumer, at their home.

-

A member of a five person team tasked with developing a solution to a chosen engineering problem.

I was the primary owner of the following project items:

Cable spool and Retractor.

Component mountings.

In charge of integration of all components into a seamless product.

Renderings and consumer marketing.

-

Product Development, Design for Manufacturing, CNC & CAD/CAM, Circuit Design, Motor PWM Control, Rapid Prototyping, Front-end Product Marketing, FEA, Dynamic Analysis, Electronics Analysis

How did me and my team develop this product? With a year of work and constant product evolution.

Prototyping Phase

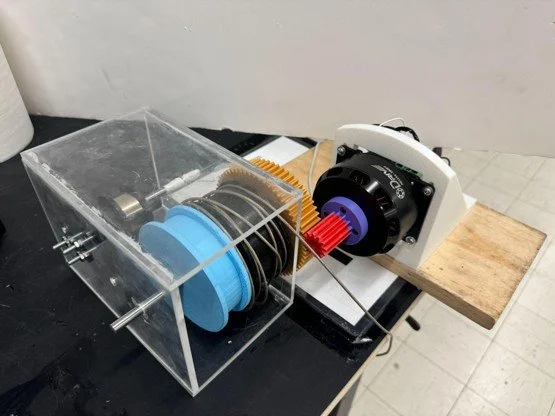

The prototyping of a cable input system with a motor providing electronic resistance that emulated a piece of commercial gym equipment.

This was the first step toward our goal of a portable cable unit. We were able to demonstrate that a continuous electronic resistance could be geared up or down depending on the attached gear ratio.

Materials and Processes: 3D printed parts, laser-cut acrylic sheeting, O-Drive M8325s (torque control motor), variable power supply, Arduino UNO

Prototyping the selection of different gear ratios and a discrete, variable, transmission, took several iterations. This was a complex process, though not as bad as a automotive transmission with continuously engaged gears. Our design assumed that when the device was not in operation, the gears were not rotation, so NO CLUTCH!

Materials and Processes: 3D Prints, Metric hardware

Alongside the gear ratio placement, the gear engagers had to be designed to allow for seamless transitions between the different gear ratios. This was perhaps one of the most difficult steps in the process, as the engagers could only be manipulated along their transmission shafts and had to seamlessly rotate into its respective gear ratios.

Whatever it is, the way you tell your story online can make all the difference.

Materials and Processes: 3D Prints, Nylon Prints, SLA Prints

Final Development Phase

In this phase of the development, the prototypes for each individual component were assembled in a few separate iterations and then refined in CNC & CAM operations.

Analysis Phase

Along with the final design phase, different sets of analysis were completed to ensure the product met safety and functionality requirements. For the full analysis report, click here.